Peel Strength Test of Copper Foil for Flexible Copper Clad Laminate

Release time:

2022-03-05 09:56

Abstract:This paper introduces the example of using Kunpeng BOYI 2025 electronic universal material testing machine, with 500N pneumatic double push tensile fixture and flexible copper clad laminate peeling fixture, according to the IPC-TM-650 test method manual section 2.4.9-1. the peeling strength of the covering copper of flexible dielectric materials, the example of the peeling test of the flexible copper clad laminate is carried out, and the adhesive strength between the copper clad layer and the substrate is characterized by the peeling strength. the test results show that, the use of Kunpeng BOYI 2025 electronic universal material testing machine can fully correspond to the peeling test of flexible copper clad laminate.

Key words:Kunpeng BOYI 2025 electronic universal material testing machine flexible copper clad laminate flexible dielectric material Peel test

Flexible copper clad laminate (FPC) is a highly reliable, excellent flexible printed circuit board made of polyimide or polyester film. FPC is also known as flexible circuit board, flexible circuit board. FPC through the flexible thin plastic sheet, embedded circuit design, so that a large number of precision components in a narrow and limited space, so as to form a flexible flexible circuit. This kind of circuit can be bent, folded, light weight, small size, good heat dissipation, easy installation, break through the traditional interconnection technology. In the structure of the flexible circuit, the constituent materials are insulating film, conductor and adhesive. One of the important role of the adhesive is to bond the insulating film and the conductive material together. The quality of the paste will affect the reliability and service life of the flexible copper clad laminate. Therefore, the test of the adhesive strength is very necessary for the flexible copper clad laminate, and the adhesive strength is characterized by the peel strength. This application introduces the peel strength test of the flexible copper clad laminate.

The pneumatic double-push stretching fixture and flexible copper clad laminate peeling fixture equipped by Kunpeng testing machine can fully meet the requirements of the standard. The pneumatic double-push fixture can quickly clamp samples and improve the testing efficiency. The flexible copper clad laminate peeling fixture is specially developed for this kind of test, which has the advantages of high precision, small resistance and accurate angle limit, which can ensure the stability and angle maintenance during the peeling test and ensure the accuracy of the results, in addition to the fixture, the high precision of the main machine of the testing machine and the acquisition frequency of more than 1000HZ can completely record all the characteristic data in the stripping process, provide accurate and reliable test data for users, and cooperate with intelligent testing software to provide various test curves such as single sample, multiple samples, double coordinates, etc. at the same time, so that different users can have a good interactive experience and escort the research and development, quality and product control of the enterprise.

1. Test part

1.1 instruments and fixtures

BOYI 2025-001 electronic universal testing machine

500N pneumatic double push stretching fixture

Flexible Copper Clad Laminate Stripping Fixture

Smartest software

1.2 analysis conditions

Test temperature: room temperature about 20 ℃

Load sensor: 1000N(0.5 level)

Loading test rate: 50.8 mm/min

1.3 samples and processing

In this test, a sample with a fixed bonding width of 3.00mm is selected, and the surface of the copper foil is reinforced with a special tape. Peel the sample for a certain distance in advance. The peeling end should ensure that the copper foil and the adhesive tape are well adhered to avoid division or edge damage, and no fracture occurs during the peeling process. At the same time, the peeling end should be long enough to be fully clamped by the upper clamp. The peeling test requires that the clamping end of the tester clamp is always perpendicular to the substrate for peeling.

2 Introduction to the test

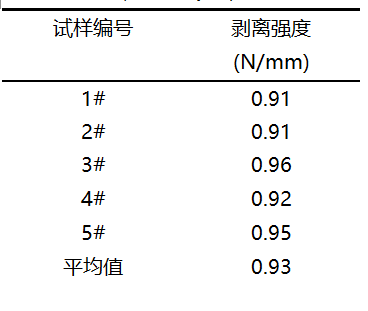

BOYI 2025-001 electronic universal testing machine is used for the test. The back of the film layer of the sample is pasted on the rotating drum of the peeling fixture through double-sided adhesive tape. The copper foil is clamped in the upper fixture, and the two are in a vertical peeling state, as shown below (Figure 1). The test was carried out at a rate of 50.8 mm/min.The force and displacement data during peeling were measured, the average peel force during the peeled state was taken, the peel force was obtained and the peel strength data was calculated (Table 1), and the peel curves were generated (FIGS. 2-3).

Fig. 1 Test System (Host, Fixture)

3. Results and Conclusions

3.1 test results

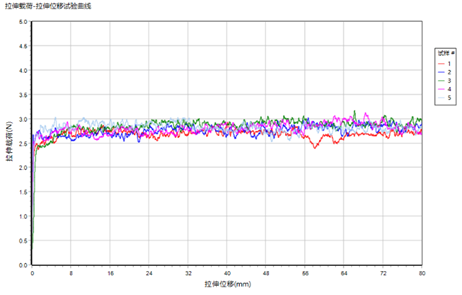

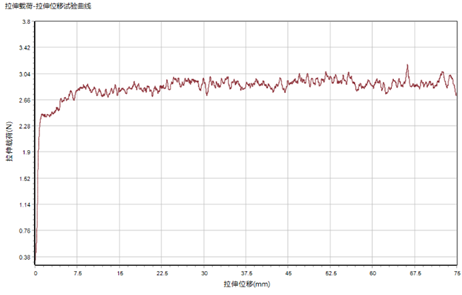

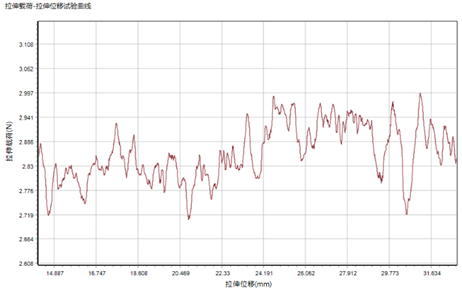

After the test, the load-displacement curve of the sample peeling test is shown in (Figure 2~3). During the peeling process, the slight force value fluctuation signal is captured by the host to form a stable peeling curve. Using the test software, the data such as load and displacement can be obtained on the curve, and the average peeling strength can be obtained. The specific test results are as follows (Table 1).

Fig. 2 Peeling curve (multi-specimen)

Local amplification of single specimen

Fig. 3 Peeling Curve (Single Specimen)

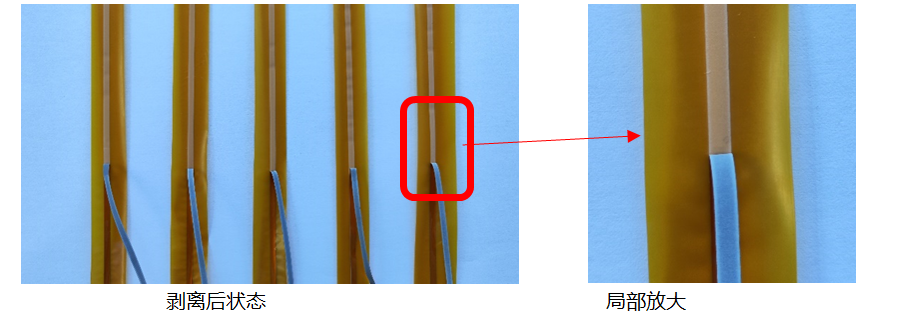

Fig. 4 Sample Peeling State

Table 1. Test results

It can be seen from the above (Table 1) data and the sample state after stripping that during the whole test process, the sample stripping state is stable, the fluctuation is very small, and there is no abnormal stripping phenomenon. The average values of the results of the five samples are very close, and the difference between the maximum value and the minimum value is within 0.2N/mm. From the results of this test can be reflectedKunpeng BOYI 2025-001 electronic universal testing machine with high precision and high stability.

4. Conclusion

To sum up, Kunpeng BOYI 2025-001 electronic universal testing machine, 500N pneumatic double-push tensile fixture and flexible copper clad laminate stripping fixture can fully meet the requirements of section 2.4.9 of the "IPC-TM-650 test method manual" section 1-the peeling strength standard of copper covering for flexible dielectric materials, and complete the test with high efficiency and high quality. Through the high-precision and high-sampling rate test system, the mechanical data of the copper clad laminate can be obtained, and it is stable and reliable. This is very important for the technological development of the flexible copper clad laminate industry. It can provide data support and technical support for the product development, quality management, and the standardization and standardization of the industry.

Recommended News

Welcome to use the testing machine to configure the auxiliary system!

Thank you for using this system.

Just answer a few questions about the experiment to create a testing system that suits you.

If you have multiple answers to a question, please choose the most important answer.

If you have any matters that need to be confirmed, please click this button to contact us.

CONTACT US