Study on Puncture Test of Lithium Battery Separator

Lithium-ion secondary batteries, also known as rechargeable batteries (hereinafter referred to as lithium batteries), are widely used as energy sources in the fields of information terminals and consumer electronics due to their high energy density and high battery voltage. In recent years, the scope of its application has gradually expanded to the field of daily life (including hybrid electric vehicles, etc.), and the demand will further increase in the future.

Among the components of the lithium battery, the lithium battery separator prevents contact between the positive electrode and the negative electrode while functioning as a spacer that allows lithium ions to pass through. The puncture resistance of the isolation film has a significant impact on the safe use of lithium batteries.

Lithium dendrite growth is one of the fundamental problems affecting the safety and stability of lithium-ion batteries. The formation of lithium dendrites can pierce the separator and cause the internal short circuit of the lithium ion battery, causing the thermal runaway of the battery to cause combustion explosion. Therefore, the anti-puncture ability of the isolation film has a heavy impact on battery life and safety.

The isolation membrane puncture strength test follows the standard GB/T 36363-2018 Polyolefin Separators for Lithium Ion Batteries, with 100mm/minspeed, using a diameter1mm, tip spherical R0.5The puncture needle, to10mm diameter ring fixed diaphragm, the anti-puncture ability of the isolation film was evaluated.

1. Experimental part

1.1 Instrument

BOYI 2025-001Electronic universal testing machine

500N pneumatic puncture fixture

1.2 AnalysisCondition

Test Type: Puncture Test

Load sensor capacity:50N

Test force accuracy: displayed value±0.5%

Test speed:100mm/min

Test temperature:25 ℃

Fixture:500N pneumatic puncture fixture

2. Experimental Introduction

2.1 Test Method

The use of this is500N pneumatic puncture clamp, the opening and closing of the clamp are switched by the hand switch on the right side of the clamp, the clamping force of the sample is provided by the cylinder, and the inner diameters of the upper and lower rings of the fixed sample are Ø10mm. Figure1 is the actual state of the puncture test.

Sample size long245mm, wide150mm, thick12um, provided by the special isolation membrane manufacturer (see Figure 1).

The diameter of the puncture needle used in the puncture test is 1mm, and the tip spherical R0.5.

Figure1. Isolation film sample and puncture test diagram

2.2 Test results

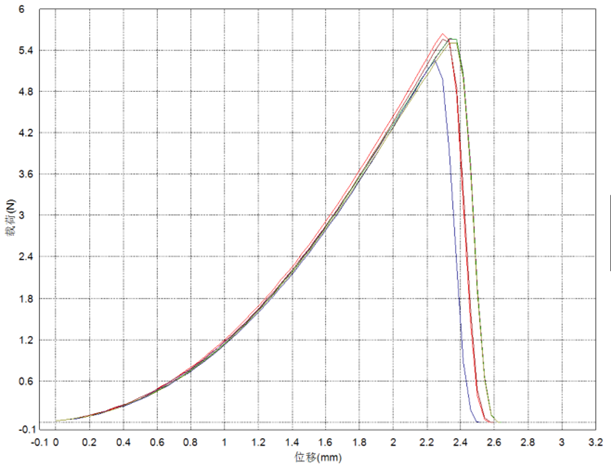

Figure 2.Puncture test curve (displacement-Load)

| Name |

Maximum point_Load |

| Unit |

N |

| 1 |

5.63924 |

| 2 |

5.55228 |

| 3 |

5.56155 |

| 4 |

5.56292 |

| 5 |

5.24382 |

| 6 |

5.50514 |

| Average |

5.51 |

| Standard deviation |

0.13771 |

Table1 Test data

Figure2with table1Puncture test curve and test result data, respectively.

It can be seen from the data that the data obtained from the same puncture needle have high consistency and small error, which shows that the whole test system has high stability.

During the test, it can be found that,BOYI 2025Good stability, high precision, stable and reliable in small force value test. The pneumatic puncture fixture is easy to operate, has high test efficiency, and has good sample fixation consistency, which ensures good repeatability of test results.

3.Conclusion

In summary, the use of this testBOYI 2025Electronic universal test,50N sensor and 500N pneumatic puncture clamp can meet the requirements of GB T 36363-2018 polyolefin diaphragm for lithium ion battery, and obtain data such as puncture strength of lithium battery separator, with good stability and high consistency.

Welcome to use the testing machine to configure the auxiliary system!

Thank you for using this system.

Just answer a few questions about the experiment to create a testing system that suits you.

If you have multiple answers to a question, please choose the most important answer.

If you have any matters that need to be confirmed, please click this button to contact us.

CONTACT US