Study on Tensile Test of Copper Foil

Abstract:This paper introduces the use of Kunpeng BOYI 2025 electronic universal testing machine and pneumatic foil special fixture, referring to the standards "GB/T 5230-1995 Electrolytic Copper Foil Tensile Strength, Elastic Modulus and Elongation at Break Test", "SJ/T 11483-2014 Electrolytic Copper Foil for Lithium Ion Battery", "YB/T 4334-2013 Metal Foil Tensile Test Method at Room Temperature", "an example of a tensile test was performed on a copper foil specimen. Evaluation of tensile strength, elongation at break and other mechanical properties of copper foil

Keywords: BOYI 2025 precision universal testing machine copper foil tensile test

Lithium-electric copper foil as a lithium battery negative collector, accounting for 5%-8% of the cost of lithium batteries, is an important lithium-electric material. Copper foil in lithium batteries not only acts as the carrier of the negative active material, but also acts as the collection and transfer of the negative electron flow. Therefore, the tensile strength, elongation, density, surface roughness, thickness uniformity and appearance quality of electrolytic copper foil have a great influence on the production process of lithium-ion battery anode and the electrochemical performance of lithium-ion battery.

Copper foil is a very thin copper strip or copper sheet with a thickness of less than 200 μm, and the light and thin lithium battery copper foil helps to improve the energy density of the battery. According to the thickness, copper foil can be divided into thick copper foil (>70μm), conventional copper foil (18-70μm), thin copper foil (12-18μm), ultra-thin copper foil (6-12μm) and extremely thin copper foil (≤ 6μm).

Copper clad laminate and printed circuit board have become the indispensable main components of most electronic products. Metal conductor foil is a conductor material for flexible copper clad laminate, including copper foil, aluminum foil and copper-beryllium alloy foil. At present, most of them use copper foil, including electrolytic copper foil (ED) and rolled copper foil (RA). Copper foil is an important material for the manufacture of copper clad laminate (CCL), printed circuit board (PCB) and lithium ion battery.

The thickness of copper foil is usually tens of microns, and it is often used in rigid and flexible copper clad laminates and printed circuit boards. The rigid board has a mechanical strength requirement and can play a supporting role; the copper foil on the flexible board is usually used in a bending, folding, and winding state, and the mechanical strength is particularly important. In recent years, due to the development of curved screen and folding electronic products, the use range is wider and the use frequency is higher. In the future, copper foil will develop in the direction of less defects, high smoothness, high strength, good ductility and thinner.

This report refers to the national and industry standards for copper foil specimen tensile test example, GB standard requirements:

1. Range 1kN, precision 0.5 tensile testing machine;

2. Sample width 13±0.1(mm), length about 200mm strip specimen;

3. The initial distance between the clamps is 50±0.1(mm), and the test speed is 50±10(mm/min).

4. Evaluation results: tensile strength, elongation at break.

1. Experimental part

1.1 instruments and fixtures

BOYI 2025-001 electronic universal testing machine

500N pneumatic foil special fixture

1.2 analysis conditions

Test temperature: room temperature about 25 ℃

Load sensor: 1000N(0.5 level)

Test rate: 50 mm/min

Distance between clamps: 50mm

1.3 samples and processing

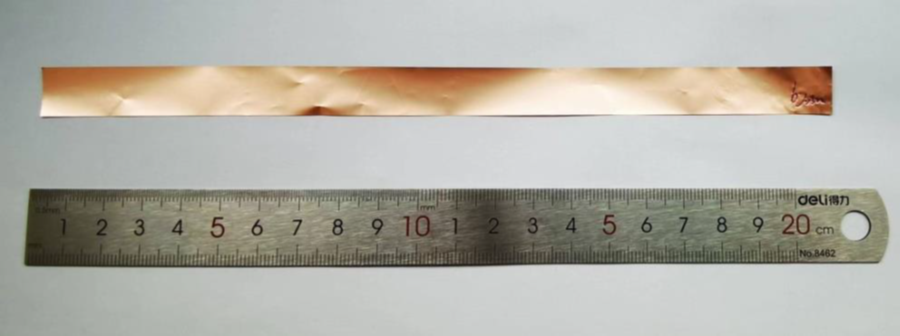

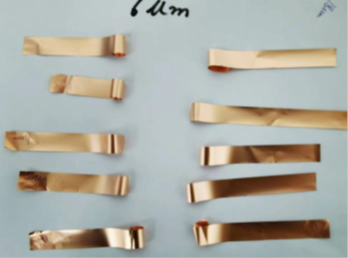

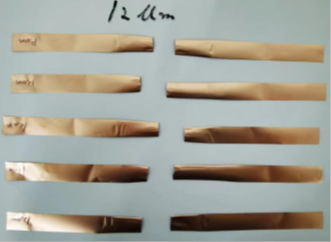

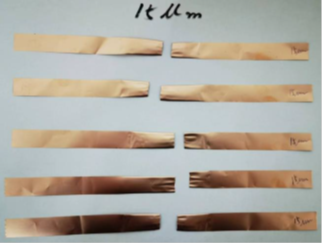

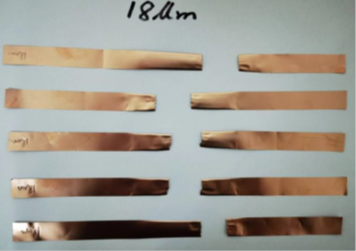

In this test, six groups of copper foils with different thicknesses from domestic mainstream copper foil manufacturers are selected (long strip samples with a length X width of 200X13(mm). See Figure 1 below); 5 samples of each group are tested. Table 1 shows the information of the samples.

Figure 1. Copper foil sample

Figure 1. Copper foil sample

Table 1. Sample information

| Specimen |

Lithium battery copper foil |

||||||

| Specimen name |

1Group copper foil |

2Group copper foil |

3Group copper foil |

4Group copper foil |

5Group copper foil |

6Group copper foil |

|

| Thickness |

6.1um |

12um |

13.8um |

16.8um |

31.2um |

64.8um |

|

| Width Clamp spacing |

13mm 50mm |

13mm 50mm |

13mm 50mm |

13mm 50mm |

13mm 50mm |

13mm 50mm |

|

2. Test Introduction

UseBOYI 2025-001Electronic universal testing machineand special fixture for copper foilThe copper foil was subjected to a tensile test (Figure 2. Test system configuration and fixture sample close-up) and a fracture test was performed at a beam displacement speed of 50 mm/min.

Figure 2. Test system composition and fixture, sample close-up

3. Results and Conclusions Group

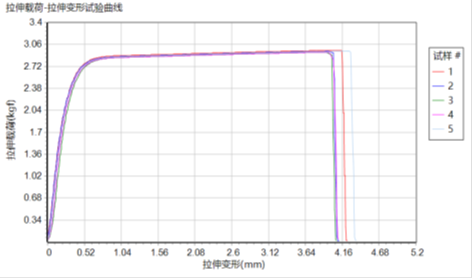

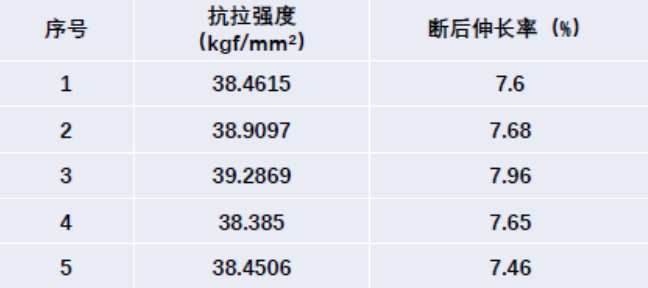

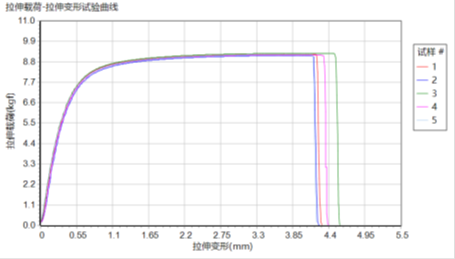

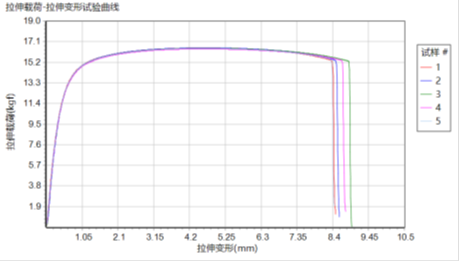

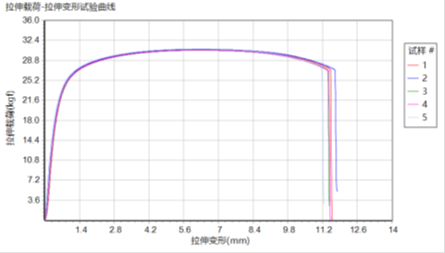

3.1 Test Results of the First Group 6.1μm Copper Foil

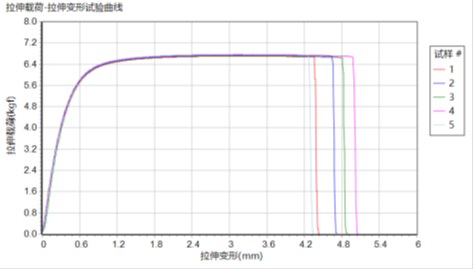

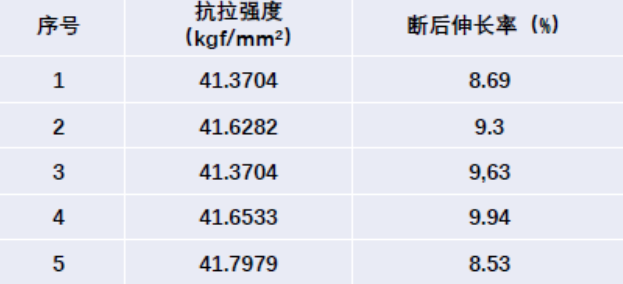

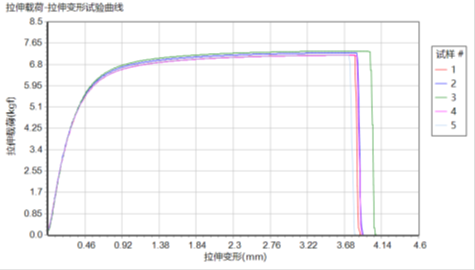

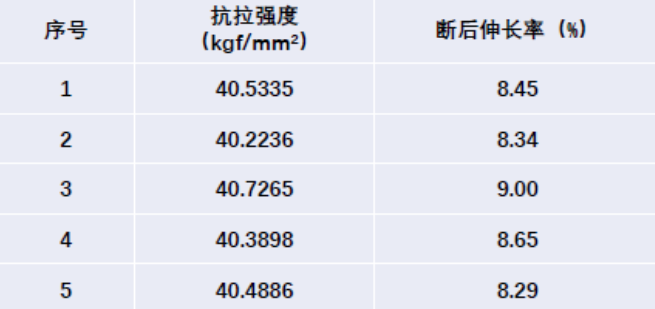

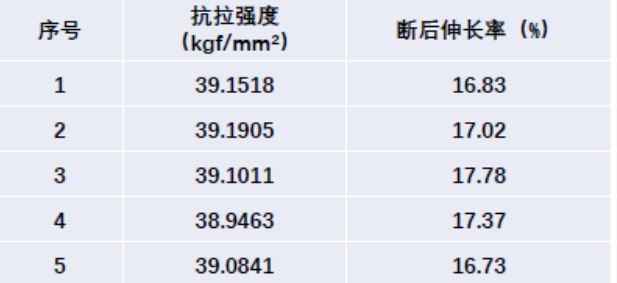

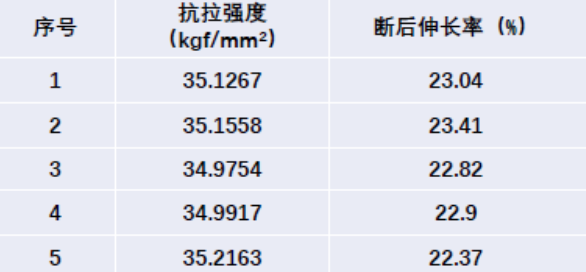

3.2 Test Results of the Second Group of 12 μm Copper Foil

3.3 the third group of 13.8 μm copper foil test results

Test results of the fourth group of 16.8 μm copper foil in 3.4

3.5 the fifth group of 31.2 μm copper foil test results

3.6 the fifth group of 64.8μm copper foil test results

From these results, it can be seen that the data of the same material and the five samples in each group are relatively stable, with little change, indicating that the uniformity of the same batch of samples is good and the test system is stable and reliable. The special fixture for copper foil selected during the test is simple to operate and convenient to clamp. All samples are broken in the middle position, and the test results are all qualified. Under the condition of not using an extensometer, the fracture elongation measured by the beam displacement is stable and reliable, which proves that the beam displacement precision of the test machine is high, and the reproducibility and stability are excellent.

4. Conclusion

In summary, the use of Kunpeng's electronic universal testing machine, 500N pneumatic foil special fixture, can meet the standard."GB/T 5230-1995 Electrolytic Copper Foil Tensile Strength, Elastic Modulus, Elongation at Break Test", "SJ/T 11483-2014 Electrolytic Copper Foil for Lithium Ion Batteries", "YB/T 4334-2013 Metal Foil Tensile Test Method at Room Temperature", "GB/T 29847-2013 Copper Foil Test Method for Printed Boards"The mechanical data of the copper foil can be measured accurately and comprehensively, and the data is stable and reliable. This is very important for the technological development of the copper foil industry and the lithium battery industry, and can provide data support and technical support for the product development, quality management, and the standardization and standardization of the industry.

Welcome to use the testing machine to configure the auxiliary system!

Thank you for using this system.

Just answer a few questions about the experiment to create a testing system that suits you.

If you have multiple answers to a question, please choose the most important answer.

If you have any matters that need to be confirmed, please click this button to contact us.

CONTACT US