Lithium battery isolation film tensile test

Abstract:This paper introduces the example of using Kunpeng BOYI 2025 electronic universal testing machine to carry out the tensile test of lithium battery diaphragm sample. This example is mainly used to evaluate the mechanical properties of lithium battery separators, and can provide reliable data for product development, quality management, manufacturing process setting, performance identification, etc.

Key words:BOYI 2025Precision universal testing machine Lithium battery diaphragm Tensile test

Lithium-ion batteries are aSecondary battery(rechargeable battery), it mainly relies onLithium ionMove between the positive and negative electrodes to work.LithiumIon battery separator (Lithium ion battery separator), in the structure of lithium batteries, the separator is one of the key inner components. For the lithium battery series, dueElectrolyteFororganic solventsystem, which requires resistance to organic solvents.Diaphragm material, generally using high-strength thin filmPolyolefinporous membrane.Lithium battery separatorRequirements:

(1) with electronicInsulation, ensure the positive and negativeMechanical isolation;

(2) has a certain aperture andporosityGuaranteed high ionConductivity, yes.Lithium ionhave very goodPermeability;

(3) Because the solvent of the electrolyte is strongly polarorganic compoundThe diaphragm must be resistantElectrolytecorrosion, with sufficient chemical andElectrochemistryStability;

(4) Good wettability to electrolyte and sufficient liquid absorption and moisturizing ability;

(5) has sufficient mechanical properties, including puncture strength,Tensile strengthWait, but the thickness is as small as possible;

(6) Good space stability and smoothness;

(7)thermal stabilityand automatic shutdown protection performance is good. Power batteries have higher requirements for diaphragms and are usually used.composite membrane;

(8) the diaphragm by thermal shrinkage to be small, otherwise it will cause a short circuit, and then causeBattery thermal runaway.

1. Test part

1.1 instruments and fixtures

BOYI 2025-001 electronic universal testing machine

500N pneumatic foil special stretching fixture

1.2 analysis conditions

Test temperature: room temperature about 20 ℃ Load sensor: 1000N(0.5 grade)

Test fixture:500NPneumatic foil professional tensile fixture test speed: 50 mm/min

1.3 samples and processing

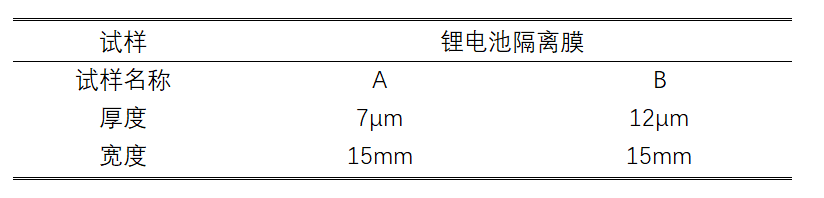

The samples used for the evaluation were two sets of lithium battery separators with thicknesses of 7 μm and 12 μm, which were subjected to longitudinal (MD) and transverse (TD) tensile tests, respectively. Table 1 summarizes a list of these samples.

2. Test Introduction

This time, BOYI 2025-001 electronic universal testing machine and 500N pneumatic foil special tensile fixture are used to carry out normal temperature tensile test on the isolation film. (Figure 1. Test system configuration and close-up of fixture sample) The fracture test was carried out at a beam displacement speed of 50 mm/min.

Figure 1. Electronic universal material testing machine and pneumatic foil stretching fixture

3. Results and Conclusions

3.1 test results

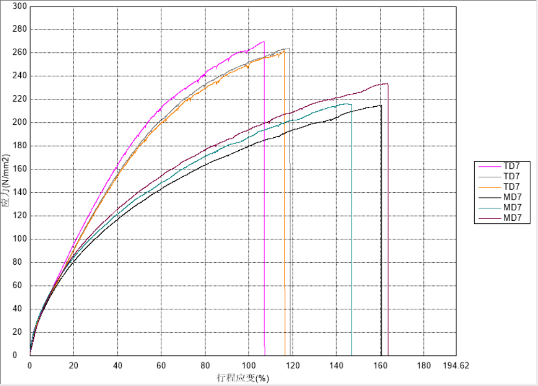

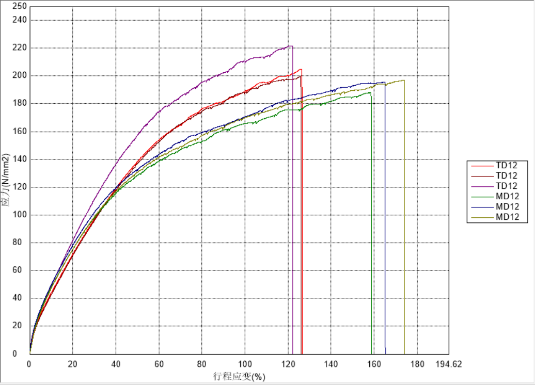

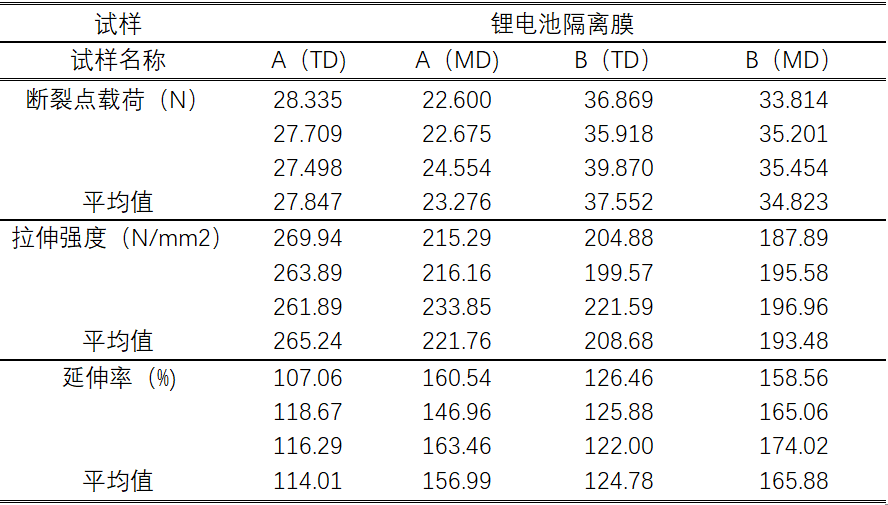

Figure 2 shows the results of the tensile test, I .e., the relationship between stress (a value obtained by dividing the test force by the cross-sectional area of the test specimen) and strain (a value obtained by dividing the extension value by the gauge length). Table 2 From the data curve statistics, tensile strength (maximum stress) and strain at break point. From these results, it can be seen that the tensile strength of each separator (Samples A and B) is an order of magnitude higher than that of the general purpose film (Sample PE) because of stretching and other treatments to improve mechanical strength and control porosity during the manufacturing process.

|

|

||

A sample B sample

Figure 2. Tensile test results

Table 2. Tensile test results

4. Conclusion

4. Conclusion

To sum up, the use of BOYI 2025-001 electronic universal testing machine can obtain more comprehensive and accurate mechanical data of lithium battery diaphragm, which is very important for the development and quality assurance of the diaphragm industry, and can provide strong technical guarantee for the standardization of the industry and products.

Welcome to use the testing machine to configure the auxiliary system!

Thank you for using this system.

Just answer a few questions about the experiment to create a testing system that suits you.

If you have multiple answers to a question, please choose the most important answer.

If you have any matters that need to be confirmed, please click this button to contact us.

CONTACT US